Konica Minolta has announced a partnership with Amiga Engineering to supply 3D SYSTEMS ProX 320 DMP metal printer and provide support, which will propel the company into the future.

The changing landscape of Australian industry means that engineering, machine shops, and jobbing workshops have been under increasing pressure to survive.

Michael Bourchier, general manager, Amiga Engineering, said, “Traditional industry, such as automotive, has moved offshore while the mining boom has faded. The country’s resources are being dug and pumped by large overseas corporations who no longer make capital investment here to have machinery or platforms made. Rather, they ship or float this equipment from Singapore or other locations around the world that are more competitive. Australians are left with being the maintenance crews of offshore-supplied equipment.”

Bourchier suggests that is a barrier to Australian creativity and innovation with Australia’s creative side is slipping to the lowest it has ever been.

According a CSIRO blog: “Despite the well publicised closure of some manufacturing sectors in Australia, manufacturing isn’t dying. Instead, like industry around the world, it’s undergoing a period of significant change as new, disruptive technologies and economic realities take hold and new markets emerge.”[1]

In an effort to keep up with world best practice, Amiga Engineering was looking for a new direction, and it found it in 3D metal printing.

Michael Bourchier said, “Amiga Engineering has been following the growth of this technology. We decided that now is the time to take the plunge into this concept area to grow it and expand the business. Without a way to reinvent the business it is probable that we would be like many other engineering shops across Australia: falling by the wayside or becoming a conservative small business surviving on whatever business comes in. We believe that 3D metal printing will take Amiga Engineering to the next level and ensure our future.

“Free geometry is the new catch-cry, where items can now be functional to the upper limits of design and not be hamstrung by the technology that it can be machined on. Amiga Engineering can add value to 3D metal printing by offering a complete service. We can not only print, we can also finish the parts to a useable state if required, and the creative genius of our design engineers can be cut loose.”

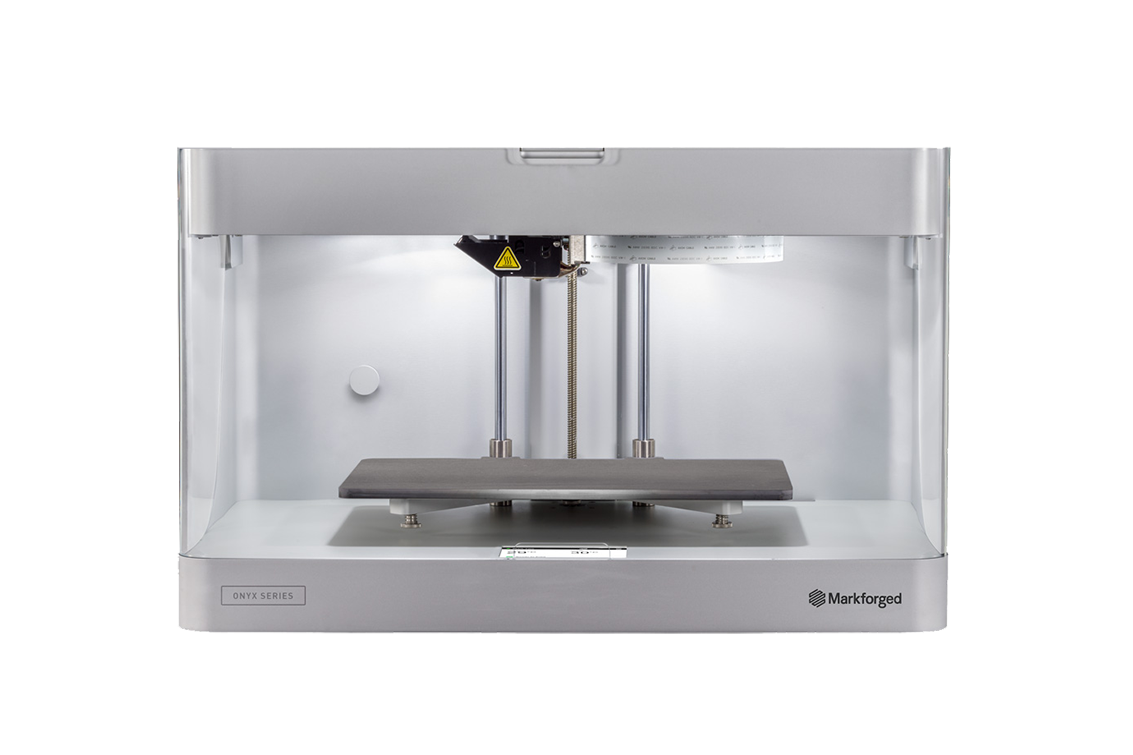

To do this, Amiga Engineering chose Konica Minolta and 3D SYSTEMS ProX 320 DMP metal printer.

Michael Bourchier said, “Amiga Engineering chose Konica Minolta because of the passion and willingness to invest in getting the idea off the ground for Amiga Engineering. Other considerations included ongoing service, longevity in the market, and who had the resources to not let us down.”

The ProX DMP 320 is a high-performance metal additive manufacturing system. It is a heavy-duty alternative to traditional metal manufacturing processes, offering reduced waste, greater speeds for production, short set-up times, and very dense and pure metal parts with leading surface quality.

Michael Bourchier said, “The 3D SYSTEMS ProX 320 DMP metal printer can swap materials through its cart system. Although this system is designed for production swap-outs of build chambers, it is the only machine on the market that could truly swap out different material types and grades in the least amount of time. As a start-up in this space, we realised very quickly we needed multiple machines for multiple materials to be able to 3D-print metal for any amount of clients. The 3D SYSTEMS ProX 320 DMP metal printer lets us do this straight up without having to invest in multiple machines.”

Amiga Engineering plans to install the 3D SYSTEMS ProX 320 DMP metal printer by the end of 2017.

Michael Bourchier said, “Amiga Engineering is excited to explore the possibilities of 3D metal printing with customers and prospects and also to help advance the industry as a whole by being a pioneer in the space, and creating use cases and applications for the technology.

“There is a lot of buzz already and we look forward to seeing where that will take us. We will be starting with applications such as medical-grade titanium for facial reconstruction and bone structures, and will look to advance into other sectors as we continue to invest in the technology.”

Ben Darling, 3D specialist, Konica Minolta, said, “3D metal printing opens up significant opportunities for companies, such as Amiga Engineering, to realise the full potential of metal manufacturing and open up new markets from medical and dental applications to aerospace and motorsports.”

Find the perfect printer for your business

Read more

Find the perfect printer for your business

Read more

Elevate your print & information technology with Insight Hub

Read more

Elevate your print & information technology with Insight Hub

Read more