3D Printers

From Concept to Reality

3D printers have the incredible potential to turn imagination into reality. Ideas that were once nothing more than a daydream or a flash of inspiration can be brought to life.

According to the old saying, “A picture is worth a thousand words.” If that’s true, what’s the value of a 3D printer? With limitless potential for home, school, and work use, a 3D printer is priceless.

Uses for 3D Printers

For home use, 3D printers offer high-tech fun. Create unique home décor, one-of-a-kind jewellery, or gifts for loved ones.

At school, 3D printers bring educational concepts to life, particularly in the STEM fields--students can hold dinosaur bones in their hands or explore robotics! With this early exposure and hands-on learning, these students may one day change our world.

While 3D printers offer quirkiness and fun at home and a classroom boost, the real transformative power is in the industrial realm.

Business Potential of Commercial 3D Printing

Commercial 3D printing has vast potential across a wide variety of industries. If you can envision it, you can use a 3D printer to shape it. Also referred to as additive manufacturing, 3D printing has applications in the arts, medicine, architecture, engineering, and entrepreneurial endeavours.

By sending digital files to 3D printers, the possibilities are as boundless as the human imagination.

An artist can create a new exhibit. A doctor can develop a prosthetic limb. An architect can design a scale model of an innovative structure. An engineer can develop a cost-effective aeroplane part. An entrepreneur can create a product no one has even thought of yet.

The Benefits of Commercial 3D Printing

With 3D printers in a commercial setting, possibilities become reality with a variety of benefits:

- Inspiration acceleration – Commercial 3D printing can condense the timeline for an idea. Instead of months, the process from inspiration to production now takes just a few days.

- IP protection – With commercial 3D printing in house, you can protect valuable ideas and products. No third-party involvement means no unauthorized eyes on your intellectual property. Plus, you'll have confidence that your company will make it to market first, and all competitors will be merely a copy.

- Collaborative creation – 3D printers enable increased collaboration between designers, engineers, and production teams, leading to higher-quality products.

- Try, try again – With commercial 3D printing, you can try different product iterations. Find flaws and improve. Test the product. Perfect it before taking the next steps.

- Better, stronger, faster – The use of 3D printers can improve each stage of your manufacturing process from concept to production. Increase operational efficiency, enhance cost-efficiency, and go to market quicker with a better product.

- Personal production – Commercial 3D printing allows for affordable customization, giving your business the power to personalize products to meet customers’ individual needs.

- Reinvent the future – 3D printers give you the power to reinvent the future of your company. Make your business more agile, find new ways to serve existing customers, and create innovative products to bring new clients on board.

Commercial 3D printing offers a wealth of opportunities for your business. Develop new products, protect your designs, and fast-track your ideas. Create entirely new business models and increase your speed to market — all by hitting print.

Options for a Commercial 3D Printer

Konica Minolta offers a variety of choices to meet your 3D printing needs:

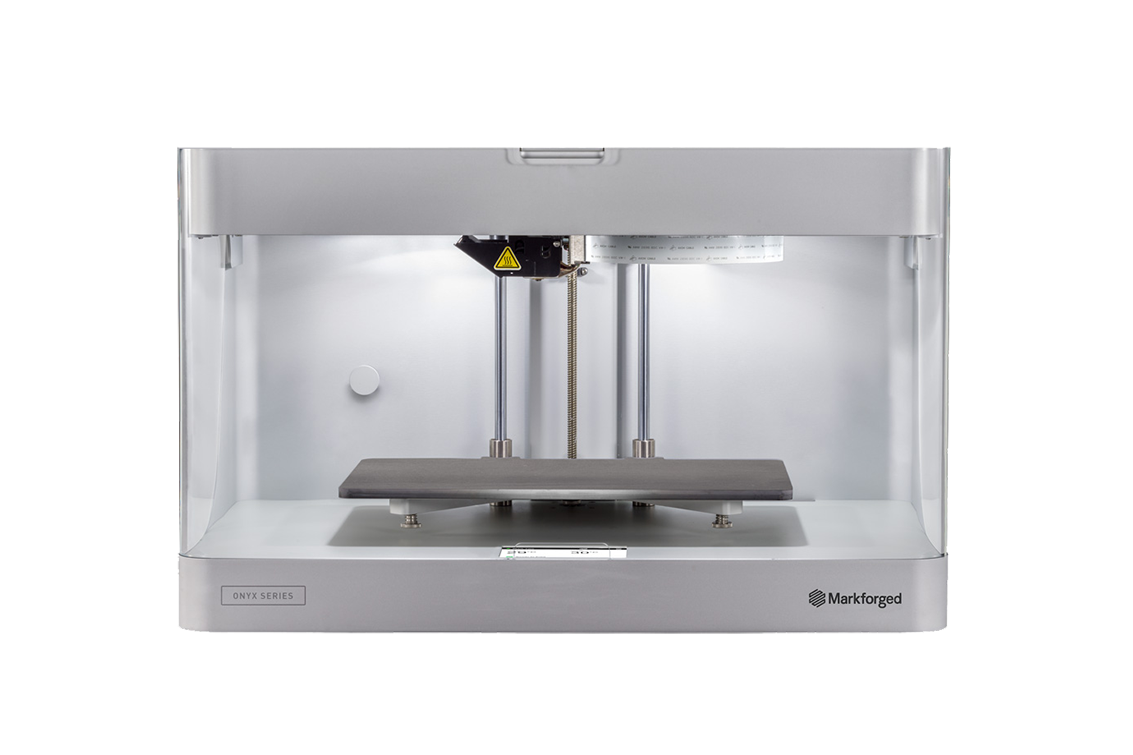

Composite 3D Printing

Highly advanced, with the ability to print cost-effectively using materials including nylon, chopped carbon fibre, reinforced continuous fibre, and metal. Available in desktop series or industrial-grade large format.

Digital Light Printing Technology

The Figure 4 from 3D Systems is scalable, fully-integrated, and ultrafast. It offers improved throughput and 20% lower parts cost.

ColorJet Printers

The ColorJet series is known for its ability to print stunning, full-colour parts at high speed and low cost.

MultiJet Printers

These 3D printers are ideal for printing precise, durable, high-definition prototypes, moulds, patterns, and end-use parts in-house.

Direct Metal Printers

Using additive manufacturing and a high-precision laser, these printers attach layers of metal powder without glue or binder liquid. Suitable for prototypes or a production series of up to 20,000 units.

At Konica Minolta we have a global team of highly skilled engineers available to support you in creating innovative complex metal parts. Our 3D Metal Printers have a range of benefits that make them suitable for a range of industries such as:

- Aerospace and defence

- Engine Component Manufacturing

- Medical Technology

- Patient-Specific implants (PSI)

- Dental Applications

- Jewellery and art objects in metal and ceramics

Our team of dedicated service and application engineers can help you to define the best material solution for you with our range of material choice, including reactive metals and ceramics.

Proven Industry Standard Metal 3D Printers

When you need 3D Metal Printing that’s industry standard, our range can offer you an industrial option for the production of metal parts.

Get a high-performance, high-quality alternative to traditional manufacturing processes, with reduced waste, greater speeds for production, short set up times and the ability to produce complex assemblies as single parts.

Our 3D Metal Printing process builds fully dense, chemically pure metal parts from 3D CAD data by melting fine powder with a laser beam, layer by layer. Break limits to part complexity with layer sizes ranging from 5-30 microns – giving you better part accuracy, surface finish and feature detail resolution.

A host of other benefits of our Metal 3D printer range offer you:

- 30% Increased efficiency in metal printing with direct integration of cooling channels into the blow mold with conformal cooling.

- A simplified assembly using a single-burner component containing nine under-cuttings and six internal cavities.

- Mass customisation capabilities with the ability to design and manufacture 1:1 perfectly fitted patient specific medical grade parts – giving you the cutting edge in 3D metal printing.

- Reduced operating costs through efficient consumables management systems.

- High precision next generation Additive Metal Manufacturing which will radically improve part design and produce products, components and tools with reduced weight, increased functionalities and better manufacturing agility.

- Enhanced fluid flow with advanced, high-performing turbine inlet guide vanes which have computed fluid dynamics and improved design giving you a 70% reduction in predicted shock intensity.

SLS 3D Printers

Expand your manufacturing capabilities with production-grade materials. Produce tough, functional nylon parts on site, on demand.

With the ProX SLS 6100 system, you can realise best-in-class part quality with production-grade nylon materials, fast build times, automated production tools and a 20% lower total cost of operation over similar printers.

- ProX SLS printers combine exceptional 3D mechanical properties with additive manufacturing speeds

- Manufactured parts show outstanding resolution, surface finish and edge definition

- Automated production tools, powder handling and recycling functions, and mobile production controls allow you to get the most from every second

- With remarkably high throughput, material efficiency and process consistency, the ProX 6100 and 500 Plus lower your total cost of ownership

- It's easy to directly produce short runs of complex or one-off customised products

Produce Tough, durable parts from a wide material portfolio that has been optimised, validated and tested to ensure quality, with uniform 3D Mechanical properties.

Stereolithography 3D Printers

When you require versatility, precision, and accuracy, SLA provides the perfect form and fit.

Material Extrusion Printers

Y Soft eDEE Solution provides secure and smart print management features with an accounting system to support cost recovery and management. Ideal for creating colourful 3D models in fast-paced, shared spaces.

Contact our team at 1800 789 389 for a quote. We're happy to help you decide which 3D printer will best fit your needs and answer any questions you may have.