Rethinking digital transformation for future print… AI, smart factories, sustainability, Industry 5.0 – and above all, human experience. These forces are reshaping the print landscape at unprecedented speed. For the first time, there is broad recognition that digital print has moved firmly into the mainstream, powering innovation across a highly connected global economy.

The push towards more efficient workflows, combined with rapid advances in automation, continues to accelerate digital print adoption.

A new year with a focus on global supply shifts and rising consumer demand for sustainability, digital printing will in many cases directly compete with established analog print processes. Offset, in particular, will feel the pressure.

The exciting evolutions underway in industrial and commercial print are widespread and will help our customers realise their ambitions, but what other big touchpoints will impact 2026 and beyond?

Here are the key trends we see influencing consumer, brand, and customer thinking in the years ahead.

Trend 1: The Unstoppable March of Digital Production

The most dynamic and fastest growing segment of a worldwide print market undergoing fundamental change – that’s digital printing! Technological advances are enabling new business models across multiple print segments, displacing legacy platforms and opening new commercial opportunities for print service providers.

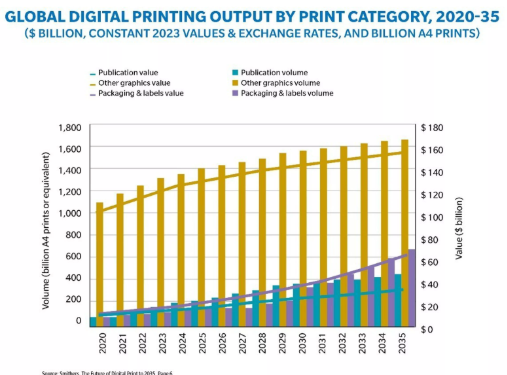

A landmark study from research experts Smithers1 confirms the scale of the shift. Digital printing is now firmly established in books, mailings, display, security and labels with adoption in packaging, magazines and commercial print2.

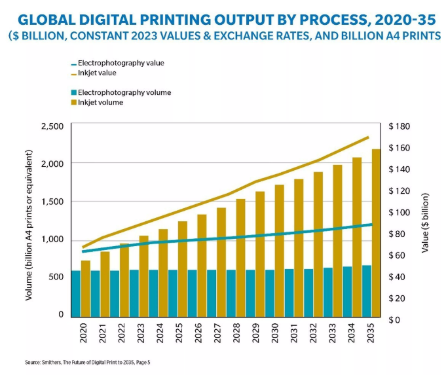

According to Smithers, digital print will account for 22.5% of the global value of all print and printed packaging, increasing by almost 50% from $167.5 billion in 2025 to $251.1 billion in 2035. And whereas inkjet technology is increasing by the biggest volume and value, toner production is expected to grow at a compound annual growth rate (CAGR) of 1.9% in the same period to 2035.

Smithers, The Future of Digital Print to 2035, Page 5 Smithers, The Future of Digital Print to 2035, Page 6

Trend 2: Automated Approach to Combat Staff Shortages

Recruiting and retaining skilled staff remains a challenge across the print industry. As a result, investment in robotics and automation systems is accelerating, helping organisations maintain productivity and build long-term resilience.

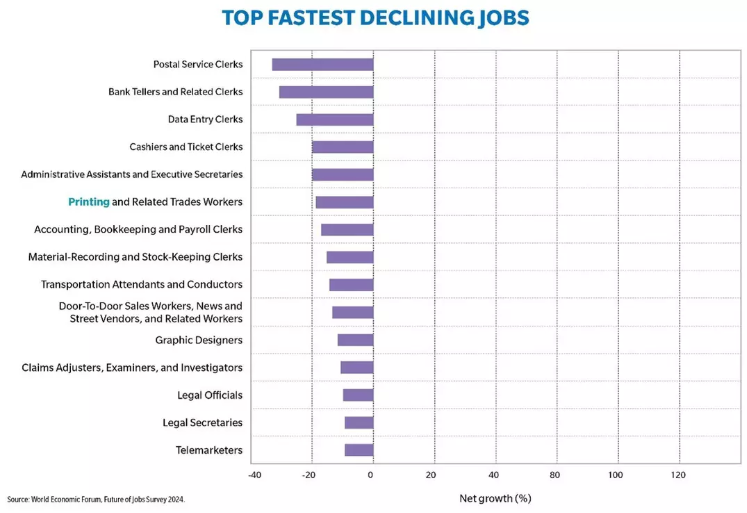

Experts from the World Economic Forum3 forecast some 2 million printing and related trade jobs will disappear in a five-year period to 2030, around 20% of the workforce. “Broadening digital access, AI and information processing technologies, and robots and autonomous systems are the primary drivers for this decline,” it states.

Trend 3: Technology that Eliminates Costly Reprints

In high-speed print environments, every second and every sheet counts. This is why the industry is prioritizing technologies that prevent errors, paper jams, and ensuring flawless output, with less intervention and reduced risk of costly reprints.

Our Intelligent Media Sensors answer these everyday problems:

The IM-104 uses six advanced sensors to instantly identify paper characteristics, eliminating manual adjustments and ensuring optimal settings.

The IM-105 adds even greater precision, measuring paper size and detecting subtle cutting variations – again, with minimal operator interventions.

These innovations help printers maintain consistency, reduce downtime and protect margins.

The Printing and Related Trades is amongst the top-fastest declining job sectors4

Trend 4: Predictive Intelligence Becomes the New Standard

Unplanned print issues may soon feel like a thing of the past. Predictive maintenance (PdM) continues to evolve, with machine learning models increasingly able to anticipate faults before they occur. As these systems mature, print environments benefit from more consistent uptime, fewer disruptions, and automated adjustments that keep production running smoothly with learning models increasingly able to anticipate faults before they occur. As these systems mature, print environments benefit from more consistent uptime, fewer disruptions, and automated adjustments that keep production running smoothly.

Konica Minolta in Australia is leading the way in Automated Quality Adjustment (AQA) which is reducing manual intervention and delivering more predictable output. AQA automatically performs daily image stabilisation tasks, producing charts at startup, diagnosing image quality, and correcting defects without operator intervention. This is particularly beneficial for print rooms with fast turnaround expectations or varying operator skill levels.

AQA can save around 20 minutes of operator work time per day by automating image colour calibration and setup, enabling teams to begin production with stable quality from the first sheet. AQA also supports proactive service. Diagnostic data is shared remotely so technicians can identify issues in advance and arrive prepared, reducing onsite repair time and avoiding downtime. The result is more uptime, fewer errors, and greater confidence in print consistency, while maximising print efficiencies.

Trend 5: Remote Support for Faster, More Efficient Recovery

Even with predictive maintenance, unexpected issues can still arise. With uptime more critical than ever, remote servicing continues to play a key role in how Australian print operations stay productive.

In 2025, Konica Minolta Australia supported many IP/PP service incidents through remote diagnostics and assistance. Our remote support services allow operators and customers to resolve issues over the phone with our dedicated technical Help Desk professionals. The team uses a range of diagnostic tools to identify issues on site and work through resolutions that keep customers printing without the need for a technician to attend.

Resolving issues remotely takes 95 percent less time than an in‑field service visit. This significantly reduces disruption and helps customers return to full operation much sooner. Across the year, this translated into 13,926 additional hours of uptime delivered to Australian customers through remote support 5.

Remote service strengthens operational resilience by enabling faster diagnosis, quicker recovery and more efficient allocation of technical resources. The result is higher device availability and more consistent performance across production and industrial print environments.

Trend 6: Local Market Shifts Drive Demand for ShortRun, HighImpact Labels and Packaging

In Australia, the strongest forces shaping print in 2026 aren’t topdown packaging mandates but rapid shifts in market behaviour. Brands are updating packaging more often, running more versions, and responding faster to retailers, seasonal launches, and competitive pressure. This drives growth in shortrun, fast turn-around digital print.down packaging mandates but rapid shifts in market run, fastturnaround digital print.

At the same time, Australian brands are leaning into premiumisation. Craft beverages, boutique food producers, health and beauty categories and rising private label products are all demanding high-quality labels, strong colour accuracy, white ink capability and digital embellishment. These requirements favour digital production over traditional analogue, especially for small to medium runs.label products are all demanding highquality labels, strong

Consumers are also expecting packaging to do more. Many brands are adding QR-based engagements, provenance, authenticity checks and dynamic content, which makes variable printing and flexible versioning critical. Digital presses make it easy to incorporate 2D codes, personalise content, and keep artwork agile without the setup burden of analogue.based engagements, provenance, authenticity checks and dynamic content, which makes variable printing and flexible versioning critical. Digital presses make it easy to incorporate 2D codes,

All of this means digital print continues to thrive in Australia’s label and packaging market. Printers who can deliver fast changeovers, consistent colour, opaque white, variable data and shortrun economics are best placed to grow as demand for flexible, high impact packaging continues to rise.run economics are best placed to grow as demand for flexible, highimpact packaging continues to rise.

Looking Ahead – Shaping a Digital Future

As 2026 unfolds, printers face a market defined by transformation and opportunity. From digital printing and personalization to cloud-based ERP systems and automation, innovation will be key to competitiveness.

One thing is certain – and it’s not just our opinion: the analog-to-digital transformation will keep advancing into more valuable market niches.

As Smithers notes 6, there will be a significant increase in digital printing over the next decade, stating: “…digital printing will fare much better than analog alternatives” because it better meets the needs of many brands, end users, and sustainability-driven markets.

The momentum of digital print is growing. Watch this space.

References:

- Smithers, The Future of Digital Printing to 2035, Executive Summary, Page 8

- Smithers, The Future of Digital Printing to 2035, Executive Summary, Page 9

- World Economic Forum, Future of Employment Report, Page 19

- World Economic Forum, Future of Employment Report, Page 19

- Konica Minolta Australia own service statistics, FY 2025

- Smithers, The Future of Digital Print to 2035, Page 18