Customer Success Story: Methodist Ladies College

Methodist Ladies’ College is one of Australia’s leading independent girls’ schools, internationally renowned for its extensive curriculum choice, cutting edge approach to education, varied learning experiences, and outstanding academic and co-curricular results. With more than 138 years’ experience in educating girls to be well-informed world citizens, the College continues to challenge and innovate as an educational leader.

Summary

“Konica Minolta has provided MLC with technology to enhance the quality education we provide, which equips students with skills of the future and prepares them for science, technology, engineering, arts and mathematics careers.”

– Simon Corkeron, Learning Technology Consultant, MLC

The Challenge

- compact 3D printers were required to install in a collaborative space

- machines needed to be easy and safe to operate by students

- faster machines required to support the growing demands from students and staff

A part of the vision at MLC is to lead by engaging with new technology and incorporating innovation into learning. The College had previously introduced 3D printing machines to give students access to innovative technology.

However, the requirement that a trained operator be present when the machines were in use meant the printers had to be installed in non-classroom areas such as the library and Art House. This had some effect on student engagement with the technology as they were required to book in a time to print when a supervisor could be present as a safety precaution. The smaller number of 3D printers were also unable to support larger class-sized projects.

The Solution

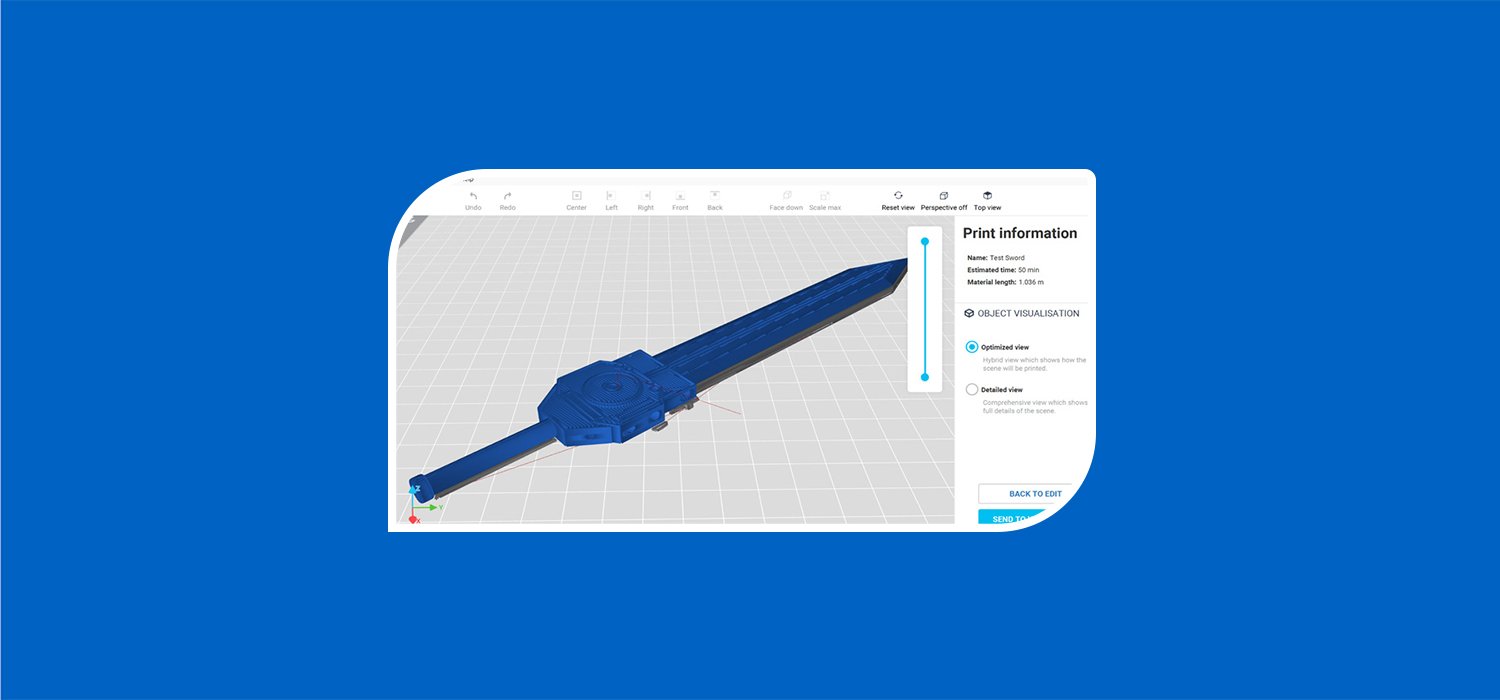

Konica Minolta approached MLC to trial the YSoft be3D eDee 3D printing solution, which is designed specifically for schools’ unique requirements. The YSoft be3D eDee printer is a compact machine that is easy to use, prints quickly, and uses safe materials that are free from harmful chemicals. With Konica Minolta’s comprehensive service offering, any problems are taken care of by trained technicians who can be on site next day.

Students can print safely as the be3D eDee 3D printer features a lockable printing chamber when in use, meaning students no longer require supervision and can access the machine more freely. James Berry, Corporate Services Director, MLC, said, “Student safety is a priority for MLC and so is providing innovative technology to benefit students’ learning outcomes. Konica Minolta provided MLC with a solution that incorporated both of these while still being affordable. MLC quickly established that the YSoft be3D eDee 3D printers could provide multidiscipline benefits to both students and staff.”

Customer Benefits

- self-locking printing chamber for student safety and non-toxic materials

- set up in a collaborative environment with easy access for students and teachers

- easy to use and fast printing

- engaged students and teachers in innovative learning, creative thinking and using future technology

The size of the be3D eDee printers meant they could be placed in a collaborative, accessible location for students and teachers. Students can easily upload their designs into the 3D printing queue and access their job when at the printer by scanning their existing ID card.

James Berry said, “The bank of 3D printers Konica Minolta provided quickly became a hub of energy and innovation. Because students can use the be3D eDee 3D printers easily and without teacher supervision, they’ve become a popular addition to enhance student projects and assignments.”

Now that the printers are easier to access and use, 3D printing has captured the attention of many students across various disciplines who are finding creative ways of using it in their projects. One student designed and printed a 3D model of a castle in England, based off satellite images, as a part of her history assignment. Simon Corkeron, Learning Technology Consultant, MLC, said, “3D printing has certainly brought out the creative side in both students and teachers. Students are coming up with ways to use 3D printing or adding it into projects that we never thought possible.”

Teachers are also finding their own creative ways of incorporating 3D printing into classroom activities.

One subject saw students use 3D printing to make mini robots. A digital fashion class saw students print 3D jewellery, which they then fitted with electronic gadgets. Elective classes, such as robotics and prosthetics, also used 3D printing to foster an environment where students could consider solutions for real-life situations, such as designing and constructing a prosthetic arm. An upcoming project in Year 9 science will focus on the nervous system and the effects of different diseases. Students will research a disease and create a device or solution, using 3D printing, which will assist people living with the illness.

One of the largest 3D projects the College has undertaken so far involved a cohort of Year 7 students who, working in teams, were tasked with building a mini city. The students came up with the ideas and design of the city, and used the be3D eDee 3D printers to bring the cities to life.

Simon Corkeron said, “3D printing gives students the ability to visualise and see a physical model of their creation. It lets them problem solve and start thinking about innovative ideas of the future. Konica Minolta has provided MLC with technology to enhance the quality education we provide, which equips students with skills of the future and prepares them for science, technology, engineering, arts and mathematics careers.”

“The bank of 3D printers Konica Minolta provided quickly became a hub of energy and innovation. Because students can use the be3D eDee 3D printers easily and without teacher supervision, they’ve become a popular addition to enhance student projects and assignments.”

– James Berry