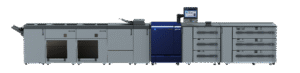

AQA automatically outputs a print quality check chart at the set time of the weekly timer or manually by the operator and uses the Intelligent Quality Optimiser (IQ-501/IQ601) built-in in-line scanner to self-diagnose whether image defects are evident. According to the diagnosis results, necessary corrections and cleaning are automatically performed, and automatic image repair is implemented.

Key features

The diagnostic results of the quality check chart are uploaded to the maintenance server, so that Konica Minolta technicians can gather the condition of the machine in advance remotely. In the unlikely event that repairs/maintenance are required, this work can be pre-organised so work time can be shortened, reducing machine downtime and maximising print up time that increases print productivity.

AQA automatically outputs a print quality check chart at the set time of the weekly timer or manually by the operator and uses the Intelligent Quality Optimiser (IQ-501/IQ601) built-in in-line scanner to self-diagnose whether image defects are evident. According to the diagnosis results, necessary corrections and cleaning are automatically performed, and automatic image repair is implemented.

The diagnostic results of the quality check chart are uploaded to the maintenance server, so that Konica Minolta technicians can gather the condition of the machine in advance remotely. In the unlikely event that repairs/maintenance are required, this work can be pre-organised so work time can be shortened, reducing machine downtime and maximising print up time that increases print productivity.

Auto Quality Adjustment

Local Stories

Specifications

| Category | Solutions |

|---|---|

| Device type | Intelligent Quality Optimiser Feature |

| Category | Automated Image Quality Self Diagnosis & Repair |

| Colour or Mono | Colour & Mono |

| Option Required | IQ-501 / IQ-601 |

| Options available PPG only | Production Options |