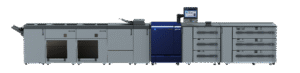

Quick and accurate

The last ten years have seen colour control, transformed, making it possible to achieve consistency from design to final product to meet today’s complex colour demands. These devices help you achieve this high level of colour accuracy - a definite advantage in today’s competitive marketplace.

Reduce waste with accurate results

Key features

Unique device profile software

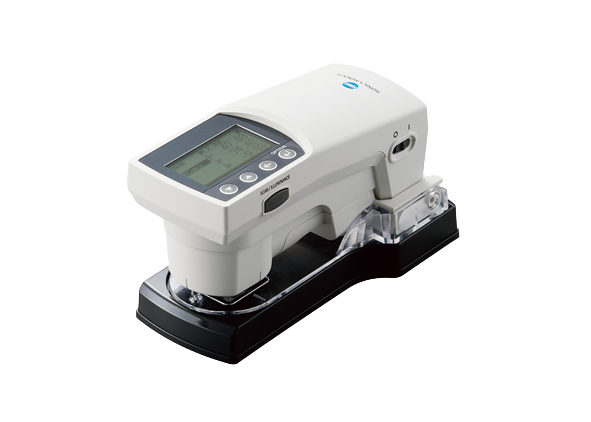

Colour measurement standard

Reliable and accurate reading of colour information that gives control back to the operator. Reduce waste and get results faster - significantly improve colour quality, minimise waste and reduce time for set up and calibration. The result is greater operational efficiency, and more consistent output quality.

Quick and accurate

The last ten years have seen colour control, transformed, making it possible to achieve consistency from design to final product to meet today’s complex colour demands. These devices help you achieve this high level of colour accuracy - a definite advantage in today’s competitive marketplace.

Reduce waste with accurate results

Unique device profile software

Colour measurement standard

Reliable and accurate reading of colour information that gives control back to the operator. Reduce waste and get results faster - significantly improve colour quality, minimise waste and reduce time for set up and calibration. The result is greater operational efficiency, and more consistent output quality.

Specifications

| Category | Production equipment |

|---|