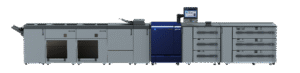

Handles wide range of media types and weights

Large range of paper weight and media types compatible

Reduced operation intervention

Key features

Easy to use

Punch dies extended life

Backed by Konica Minolta service, support and spares

Handles wide range of media types and weights

Large range of paper weight and media types compatible

Reduced operation intervention

Easy to use

Punch dies extended life

Backed by Konica Minolta service, support and spares

Specifications

| Category | Production equipment |

|---|