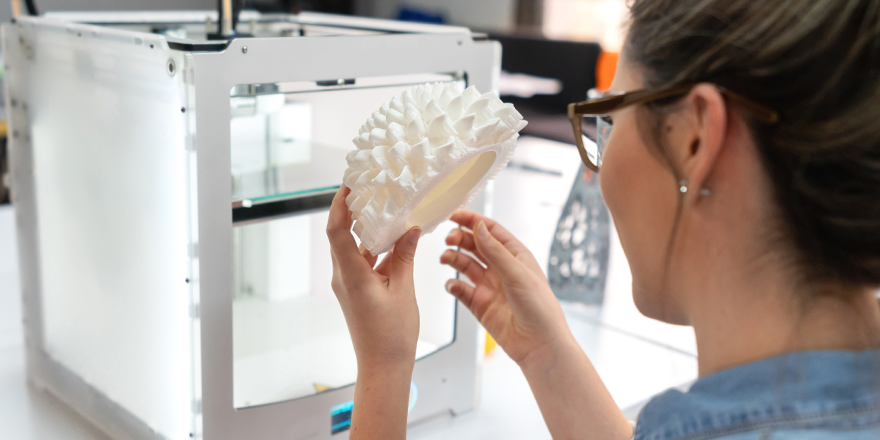

While 3D printing has been a fringe technology for decades, the numbers give some indication of how quickly it is moving towards the mainstream. Recent years have seen worldwide sales of desktop 3D printers triple with estimates that annual sales will exceed 100 million units by 2030. Driving this march towards the mainstream, Siemens predicts that 3D printing will become 50% cheaper and up to 400% faster in the coming decade.1

It’s worth pointing out that similar forecasts in the early 2010’s failed to materialize as 3D printing failed to gain traction beyond hobbyists and niche industries. However, the COVID-19 pandemic quickly changed this. Collapsing global supply chains forced many businesses and industries to explore production alternatives and 3D printing was quickly identified as an ideal solution. According to industry analysts, the pandemic saw utilization of 3D printing technology explode to become a $63 billion global market in 2021.2

But it’s not just COVID-19 that has proven to be a game changer. As the materials available for use in 3D printers have expanded, so have possibilities and applications for the technology. Gone are the days of being restricted to printing with resin-type plastics. Today, 3D printers can manufacture items using stainless steel, ceramics and even advanced alloys.3

The Australian-based orthotics company Korthotics is a fantastic case-in-point of what’s possible with modern 3D print techniques. In partnership with Konica Minolta, Korthotics has developed world-leading custom-made orthotics printed using materials ranging from plastic to Titanium, Aluminium, rubber and carbon fibers. 4

At a much larger scale, home builders have also begun using 3D print techniques in construction. One of the pioneers in the field, The Dubai Future Foundation, forecasts that 25% of new buildings in Dubai by 2025 will be constructed using 3D printing.5 It is a similar story in Germany where a three-story, five-unit apartment building was 3D printed in early 2021 in a suburb of Munich called Wallenhausen. Unlike previous 3D printed apartment blocks, this project is not a proof-of-concept but instead was rented in the general market just like a traditional apartment development.6 In an inspiring example of the potential for 3D printing construction, the San Francisco-based charity New Story has partnered with Texas construction giant ICON to design and build affordable housing for unsheltered families. The charity’s first 3D printed 50-home community was opened in early 2021 in Tabasco, Mexico, with scores of new locations scheduled for other low-cost, functional and durable dwellings.7

Even where 3D printing is not the primary construction method, it promises to revolutionize the economics and environmental impacts of the building industry. This was most clearly evidenced by a research team at the Zurich University for Science and Technology which demonstrated a technique for using prefabricated 3D print panels which reduce concrete consumption in construction projects by half.8

Looking to the residential desktop 3D printer market, MakerBot are leading the charge in creating low-priced and easy-to-use 3D printers for everyday consumers. Beyond producing affordable print hardware, MakerBot are helping create an entire ecosystem of downloadable designs that will make personal printer ownership both viable and attractive.9

In the medical arena, 3D printing has shown great promise with significant breakthroughs resulting in the ‘bioprinting’ of skin10, bone11, heart and vascular tissue. Doctors have even discovered how to print liver cells that can be used to create transplant organs12. It is truly amazing technology that presents such exciting possibilities when you consider that an average of 21 people die each day waiting for organ transplants.13 Better still, 3D printed organ replacement tissue using a patient’s own cells eliminates the danger of rejection after transplant.14 Researchers at University of Toronto also made headlines with their invention of a handheld 3D printer for skin grafts using a patient’s own stem cells.15

In the world of pharmaceuticals, 3D printing is poised to change the game too. The US Food and Drug Administration recently approved the first 3D-printed drug with a view to making a wide range of pharmaceuticals printable in the years to come.16 Considering how lucrative and heavily regulated the pharmaceutical industry is, the ramifications of this change could be enormous.

To see how 3D printing could change the game and tip the scales of power toward consumers, consider recent advancements in the printing of consumer goods such as shoes.

In the past few years, all the major shoe manufacturers, including Nike, Adidas and New Balance, have taken significant steps toward 3D printing.

To date, many of these advancements have centered on the creation of printed insoles and orthotics designed to prevent or eliminate foot pain. However, printing insoles is just the beginning. Soon we’ll be printing the whole shoe.

Former New Balance CEO Robert DeMartini admitted in 2016 that his company was working on a design for 3D-printed running shoes. “It’s really just the beginning’, DeMartini said. ‘As personalization takes the next step, and as the 3D ecosystem gains steam, we’re envisioning being able to print these in consumers’ homes.17”

Despite the potential that 3D printing offers, the fact remains that the technology has struggled to become mainstream in recent years owing to high hardware costs and limited availability of print designs. In the words of Hod Lipson in his book Fabricated, what 3D printing needs is a ‘killer app’ — the one capability that will cause it to become an irresistibly attractive option for everyday households.

According to Lipson, this killer app may well come in an unexpected form: food.

While food printers are already creating designer cookies, pastries and chocolates, the significant shift will occur when restaurants and households can use these printers to create entire personalized meals in their kitchens using 3D printing technology.18

The main value of 3D food printing lies in convenience and customization. As specialized diets become more commonplace, 3D-printed food is poised to enable more personalized on-demand eating experiences. The creator of the industry leading Foodini 3D food printer, Lynette Kucsma, predicts that by the mid 2030s, “3D food printers will become a common kitchen appliance in both home and professional kitchens, similar to how an oven or a microwave are common appliances in kitchens today.”19

Setting aside the obvious bias in Kucsma’s prediction, the trend toward printed and customized meals in consumer’s homes could be enormous if she is even half right.

Amara’s Law tells us that humans tend to overestimate the effect of a technology in the short run and underestimate the effect in the long run. While 3D printing technology may have been slow to gain traction, it’s important not to underestimate how significant this trend will be in the years and decades to come.

- Columbus, L. 2015, ‘2015 Roundup Of 3D Printing Market Forecasts And Estimates’, Forbes, 31 March.

- 2020, ‘24 Industries & Technologies That Will Shape The Post-Virus World’, CB Insights, 9 August

- Schwab, K. 2016, The Fourth Industrial Revolution, Penguin, London, p. 163.

- 2019, ‘Korthotics delivering unprecedented patient care with digital plastering introduced by Konica Minolta’, 4 November.

- Jezard, A. 2018, ‘One-Quarter Of Dubai’s Buildings Will Be 3D Printed By 2025’, World Economic Forum, 15 May.

- Lane, K. 2020, ‘Collaboration Develops First 3D-Printed Large-Scale Dwelling Unit’, Springwise, 8 December.

- Khoury, K. 2021, ‘3D-printed communities provide housing for unsheltered families’, Springwise, 8 February.

- Khoury, K. 2020, ‘3D-printing halves concrete use in construction’, Springwise, 17 July

- Rothman, W. 2014, ‘MakerBot Unveils a 3-D Printer Nearer to $1,000’, The Wall Street Journal, 6 January.

- Jacquith, T. 2016, ‘Scientists 3D Print Cartilage Using an “ink” Composed of Human Cells’, Futurism, 16 March.

- Galeon, D & Marquart, S. 2016, ‘Doctors Can Now 3D-Print Bones On Demand, Thanks to a New “Hyperelastic” Material’, Futurism, 30 September.

- Schwab, K. 2016, The Fourth Industrial Revolution, Penguin, London, p. 23.

- Ibid.

- Ford, M. 2015, Rise of the Robots, Basic Books, New York, p. 180.

- Peters, A. 2018, ‘This Portable 3D Printer Could Print Skin Over Wounds’, Fast Company, 5 August.

- Murphy, M. 2016, ‘We’re Closer To A Future Where We Can 3D Print Anything’, Quartz, 5 April.

- Ibid.

- Ford, M. 2015, Rise of the Robots, Basic Books, New York, p. 180.

- 2020, ‘Innovative 3D Food Printer Cuts Food Waste And Boosts Creativity In Kitchen’, Eurasia Review, 30 December.