The SD-450 can staple and fold up to 50 sheets of 80 gsm, which creates booklets of up to 200 pages. The SD-435 is capable of 35 sheets creating 140 page booklets.

Square folded booklets from A6 to A4 Landscape and beyond

Simple to use 7" touchscreen graphical interface with easy job setup and adjustment of applications.

Key features

Compact booklet making system, includes corner and edge stapling function as standard

High-wearing parts are built into the easy to replace staple cartridge itself. You’ll spend less time worrying about maintenance and more time making great looking booklets.

This standard feature allows output produced on other printing systems to be turned into high quality booklets.

The SD-450 can staple and fold up to 50 sheets of 80 gsm, which creates booklets of up to 200 pages. The SD-435 is capable of 35 sheets creating 140 page booklets.

Square folded booklets from A6 to A4 Landscape and beyond

Simple to use 7" touchscreen graphical interface with easy job setup and adjustment of applications.

Compact booklet making system, includes corner and edge stapling function as standard

High-wearing parts are built into the easy to replace staple cartridge itself. You’ll spend less time worrying about maintenance and more time making great looking booklets.

This standard feature allows output produced on other printing systems to be turned into high quality booklets.

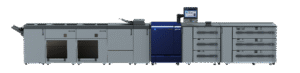

Specifications

| Brand | Plockmatic |

|---|---|

| Device type | Booklet Maker |

| Category | Production equipment |

| Output size | From 145 x 99mm to 320 x 330 (330 x 310 with optional RCT) |

| Average monthly print volume | 20K |

| Duty cycle | Max monthly volume of 40K |

| Weight (kg) | 230 kg Including Uplift Module and packaging |

| Dimension W x D x H (mm) | 1700 x 720 x 1130mm Incl. Stacker and uplift module |

| Power requirements (V / Amp / Hz) | 100-240 V; 50-60Hz; 4-2A; AC |

| Max power consumption (kW) | (Max) 400W Includes FM-400 module, during production |