-

Products

-

Office Printers

-

Production Printers

-

Industrial Printers

-

Wide Format

-

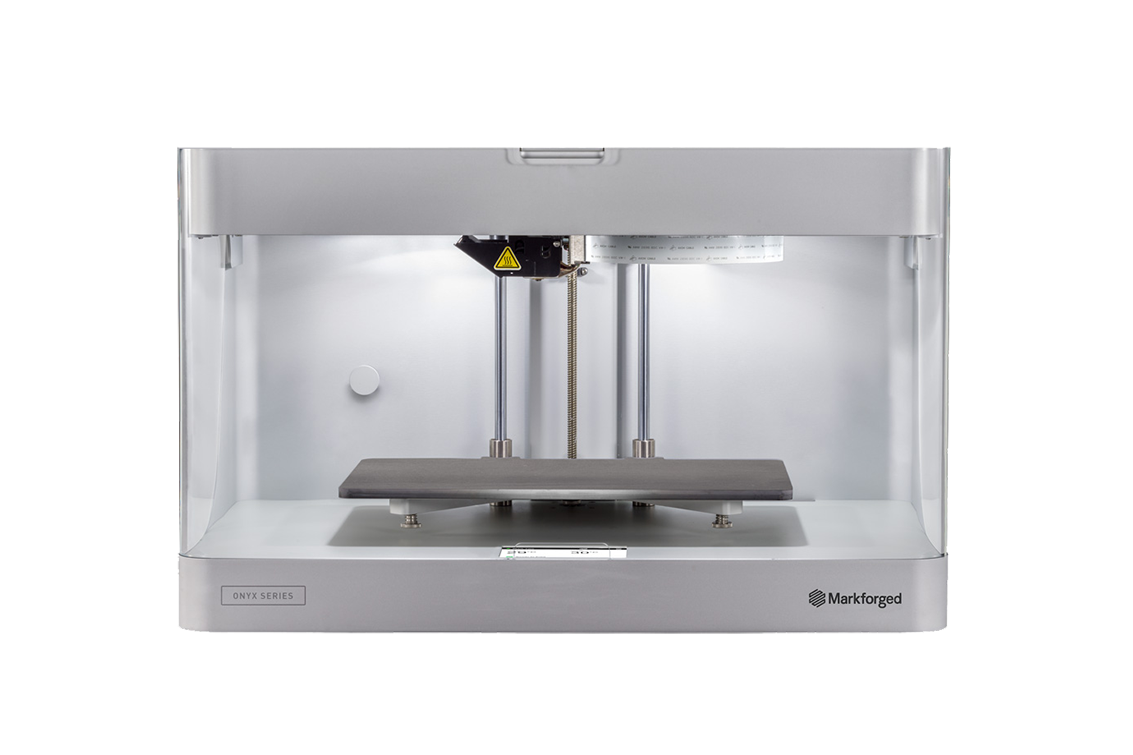

Commercial 3D Printers

-

Robotics

-

Document Scanners

- 3D Printer Accessories & Consumables

- View all

-

Find the perfect printer for your business

Read more

Find the perfect printer for your business

Read more

-

-

Services

-

Information Management

-

Managed Print

- View all

-

Elevate your print & information technology with Insight Hub

Read more

Elevate your print & information technology with Insight Hub

Read more

-

- Support

-

News

-

About

- Contact us